As a leading Battery assembler we, at AMICELL, understand that quality is a way of thinking.

We expect from ourselves to give the best product possible

The QC department is in charge for product quality – beginning with testing the single cells (as acceptance test), quality inspections while manufacturing and testing the final product – the battery pack / Charging system / LED light, conducting safety tests, performance tests and QUAL tests (MIL-STD, DO-160 etc…)

The QC tests on the battery cells:

- Conducting 100% cell tests when required.

- Assemble cells into similar groups.

The QC tests on the final product are conducted in two steps:

- Conducting all the safety tests for the battery – 100% test

- Conducting a performance tests according to the expected battery operational profile – 100% test!

These measures allow us to supply with a quality battery that will fit our customer’s needs.

Amicell Lab – single cells test

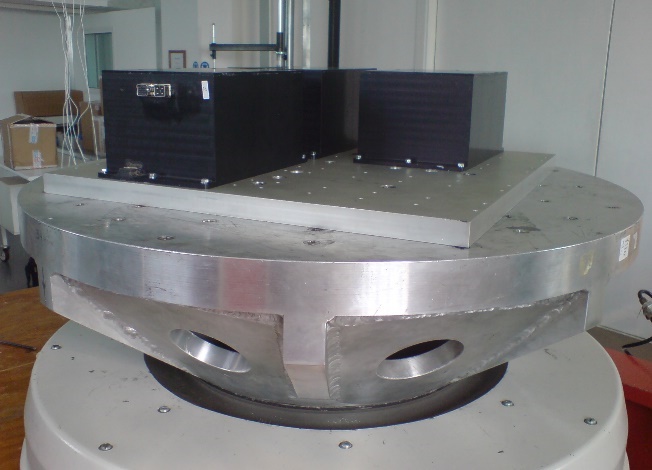

In addition, our Lab will perform all environmental tests required – from UN tests for transportation to MIL-STD tests.